Now I bet that made him happy Feenix...As I previously noted, I commend you for your persistence in making it work. I have been pretty lucky all my wildcats worked out as I wanted.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is it time for to me to give up on my wildcat?

- Thread starter Tac-O

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

fta0303

Well-Known Member

Actually a better cartridge than a .308.No advantage to that case over current factory. Sometimes a wildcat makes no sense especially if you do not have money to waste on it

I put together a 30-284 also and wanted the cartridge because I like ruger precision rifles a bunch and wanted to hunt with one although they are a little heavy. Mine gave me fits and I also thought it was a mistake untill I started neck sizing I think the lee dies sized the dimension at the shoulder, neck area .007 smaller than once fired, so I started neck sizing and the rifle shoots very well now. My load is 53 gr A4350 with a 190mk or 53 gr 414 with a 190 mk, 55 gr like you are shooting was too much pressure in my rifle. I got a lee collet neck sizing die for this round and the die is for 7.5 swiss but works perfectly with the 30-284 and the die is $30 and when checking for concentricity I have never had any problems with these lee collet dies, the needle doesn't even move. A case that measures .001 out of concentric would be a bad one for these dies. I have used lots of other types including bushing dies but these $30 dies beat them all hands down. For a body die I'm going to use a 284 body die that uses bushings and make one to suite the 30 cal.

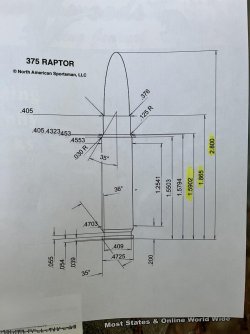

There are a number of replies on remedying the issues you are experiencing with you wildcat. I'll try to answer the question about "thowing in the towel". Presently I have put together a wildcat rifle, a .375 Raptor. I had a Ruger 77 tang safety, short action rifle that was chambered in 22-250. The rifle was an "okay" shooter, but it hadn't left the safe in years. I recently had a Ruger Gun Sight Scout in .450 Bushmaster that I bought for black bear hunting from a ground blind. I liked the rifle/cartridge, but... it had a detachable box magazine and the magazine release was located in front of the trigger guard. The last time out with the rifle, it ended up with the magazine sitting in my lap. So... I started looking for a cartridge that would work in Ruger 77 short action that was a thumper for black bear hunting. After looking and looking I stumbled upon the .375 Raptor. It showed promising ballistics, and the dimensions of the cartridge were exactly the same as the .308 Winchester, only the case neck was shortened and the mouth of the case was blown out from .308 caliber to .375 caliber. I contacted a gunsmith, Matt Cockrell (M.C. Gunsmithing), and asked him if he could put the rifle together and make sure that the rifle would feed from the enclosed box magazine without an issues. Matt told me that he could make the rifle work. So... I have the expenses of an X Caliber barrel, an X Caliber muzzle brake, installed barrel, and a cerakote finish rifle for around $1000, plus the cost of the rifle, probably in the $600-700 range. The workmanship is impeccable and the rifle does feed as it should. Now comes the kicker, the load data. This is where I ought to have done more research. Most of the load data that I can find for the 250-260 gr bullets is using Alliant 10X powder and that data is limited. There is a lot of load data using Alliant 1200R, but it could not be found. I contacted Alliant out of desperation only to be told that the powder was discontinued 1 1/2 years ago!! My research, after the fact, seems that some of the ballistics have been exaggerated quite a bit also. The rifle is ready to shoot, I have the brass all fireformed, trimmed and prepped, but I am hesitant to make some loads because I do not like limited data that I have. Forming brass was an easy process of expanding .308 Winchester with a .375 Sinclair mandrell, then full length resizing, annealing and turning the necks and trimming to case length. So yes I am considering throwing in the towel on this build. I am familiar with loading for a wildcat cartridge as I have two .270 Ackley Improved rifles built on the same Ruger 77 action. I have all of the equipment and the knowledge about fireforming and neck turning. The big drawback presently is load development and the lack of data to put the loads together. I have found some data using a burn chart using Vihtavouri N120 and N130, but these powders are also difficult to find. So again yes I am thinking about throwing in the towel with this build and selling the entire project. Plus after this build I found a Ruger 77 Hawkeye (enclosed box magazine) in .450 Bushmaster, so I really do not need this rifle. So to answer the OP question, yes I have/am considering throwing in the towel.

Attachments

Last edited:

DLJ6

Well-Known Member

I feel your concerns. I have a series of wildcats that I worked with talented gent to develop based on the 376 Steyr case back in the mid '90s as the case capacities fell in a sweet spot between -06 and Win. mag. cases. At the time, I was thinking someone in addition to Hornady would eventually run brass. We chambered these in barrels for the TC Encore platform in .338, .308 and .264 versions with a single radius shoulder. All proved efficient and very accurate. We also did a 25-284 with a radius shoulder in a Douglas blank that is likely the most accurate barrel I own. Over time I found I prefer to spend less time at the reloading bench and more time at the range. Sub calibers can be a whole new level of frustration and I don't wont elaborate on my 14 Hornet work. Don't get me wrong, I still tinker with a lot of brass but tend to save that for the winter months. I also have loads worked up for a 20BR we did years ago that I have still not fired. Hobby time management can be frustrating but I hope to allocate more time to wildcating when I finally retire in a couple years.

Lee Goodwin

Well-Known Member

That ring on the neck kinda looks like a gas check, and, interesting. If that is a recess ring in your chamber can you fill it in and re-ream the neck a tad?

it's super typical for there to be some carbon on the neck. Typical neck clearance is .004-.005" and this will have carbon on the neck, like just about any typical chamber. Infact BR shooters look for a sine wave in the carbon on the neck to tell them the brass clearance is "happy"It seems that you are getting carbon build-up on the case neck after firing, since you are having to clean with a 3M pad. This shouldn't be happening. It indicates that the neck portion of the chamber is cut a bit too big. I had a 6.5-284 built, and it came with this problem. If I recall correctly, I confirmed the problem by measuring the neck diameter on a fired case - it was larger than spec. I asked him to re-cut the chamber to 6.5 Wby RPM, he did, and that problem went away.

I see your photo of a case standing on end, with a ring of metal around the neck. It looks like this case is a fired case. I'm thinking that you resized it and got this result (?) If you try to use a properly made resizing die on a fired case that has expanded in diameter beyond spec, it might build up a shaving roll something like pictured. Just speculation, though.

If you go down to .001" clearance you won't have carbon on the necks but this isn't recommended for the average shooter as it can cause other issues.

The photo of the case with the neck all messed up was because the expander die he tried to use was not reamed for a 30 cal neck. You looked at the picture but didn't think it necessary to read the text that went along with it...????

@Alibiiv, @DLJ6, @Lee Goodwin way to keep the thread going in the proper direction

Not certain about what you mean here about keeping the thread going in the proper direction?it's super typical for there to be some carbon on the neck. Typical neck clearance is .004-.005" and this will have carbon on the neck, like just about any typical chamber. Infact BR shooters look for a sine wave in the carbon on the neck to tell them the brass clearance is "happy"

If you go down to .001" clearance you won't have carbon on the necks but this isn't recommended for the average shooter as it can cause other issues.

The photo of the case with the neck all messed up was because the expander die he tried to use was not reamed for a 30 cal neck. You looked at the picture but didn't think it necessary to read the text that went along with it...????

@Alibiiv, @DLJ6, @Lee Goodwin way to keep the thread going in the proper direction

Valley Fever

Active Member

Well put. To the OP, I've come to the conclusion that most of us can't shoot what your cartridge purports to offer over other cartridges.Biggest issue with modern wildcats is clearly laying out a well defined goal of the niche it will fill. Then going out and making very certain in the near exhaustive catalog of modern cartridges it actually fills a need worth the time and energy spent. Failing to do that causes most the wildcat angst. Gotta make the juice worth the squeeze, usually even then it's more expensive than the next closest factory offering.

If your hobby is wildcatting and that's your thing, go for it. I've come full circle on my 6mm Remington. I've looked at all the new whiz-bang 6mm wildcat cartridges and the minute differences between them and decided to rebarrel in 6mm Remington. Once I've mastered the 6mm Rem., I'll look for an existing larger caliber to master. My technique and the elements are a far bigger challenge than what cartridge I shoot.

Float that boat!

Valley Fever, consider a 6 Rem AI on your next wizz bang. 80g TTSX at 3800 is no slouch deer load vs 3600 in the std 6 Rem with 26" bbl, 10T.

Lee Goodwin

Well-Known Member

Oopsit's super typical for there to be some carbon on the neck. Typical neck clearance is .004-.005" and this will have carbon on the neck, like just about any typical chamber. Infact BR shooters look for a sine wave in the carbon on the neck to tell them the brass clearance is "happy"

If you go down to .001" clearance you won't have carbon on the necks but this isn't recommended for the average shooter as it can cause other issues.

The photo of the case with the neck all messed up was because the expander die he tried to use was not reamed for a 30 cal neck. You looked at the picture but didn't think it necessary to read the text that went along with it...????

@Alibiiv, @DLJ6, @Lee Goodwin way to keep the thread going in the proper direction

randy86314

Active Member

Maybe a bit late to the train.

So, what about your rifle is not quite right?

What you means by "clickers?"

How accurate is it?

Can you post some pics of your fired brass, of both the primers/base and the bump at .200?

More to follow.

So, what about your rifle is not quite right?

What you means by "clickers?"

How accurate is it?

Can you post some pics of your fired brass, of both the primers/base and the bump at .200?

More to follow.

clicker is when the case basically is stuck in the chamber and you need to really push up hard on the bolt handle and it makes a "click" when it whacks the top of the extraction ramp. Usually caused by over pressure loads or a miss match between die and chamber that allows the .200 line to get to large.Maybe a bit late to the train.

So, what about your rifle is not quite right?

What you means by "clickers?"

How accurate is it?

Can you post some pics of your fired brass, of both the primers/base and the bump at .200?

More to follow.

The OP has figured out his issue

General RE LEE

Well-Known Member

Saw the thread title and thought this was about a wife.

Similar threads

- Replies

- 61

- Views

- 7K