It definitely hammers! It's the most accurate gun I've owned. The majority of the problem is brass/sizing, cost of fireforming, probably need to neck turn but don't have the tools, the list goes on and on.

There's tons of info to share, so it may take a bit to get the whole picture out there.

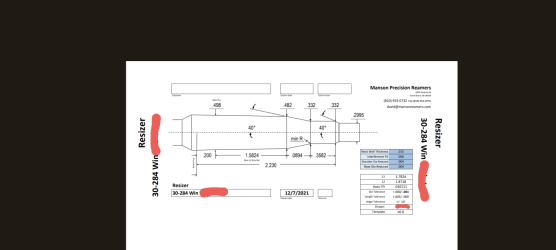

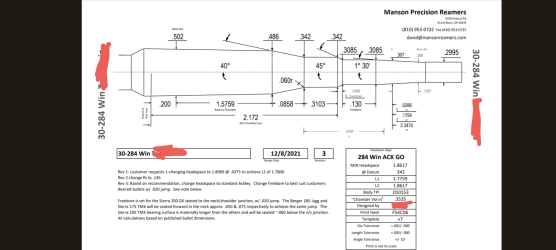

30-284 AI - prints attached, Manson reamers. I own the chamber and resizer reamer

Tikka action

Mullerworks 23" 10 twist barrel

FL sizing die is a PTG die blank, unhardened

Chambered and dies cut by Robinson Precision Rifles. He's no longer in business and I didn't hear back last time I tried to contact him last year. He seemed to be an awesome guy. Knowledgeable, easy to work with, etc. His work seemed good, however the chamber and die cuts aren't quite as smooth as I expected them to be. I know his work was at least concentric. I feel like some of the issues I'm dealing with are either from his work or from the reamers, but I'm not sure which.

My main load is

Peterson or Lapua brass (mostly Peterson)

185 juggernauts

Cci200

55.5gr h4350

2825fps

Deprime

Clean carbon off neck exterior w 3m pad

Anneal every loading

Brush interior neck

Dry graphite lube interior neck and Lee lube on body

Size FL die, bump shoulders 0.003

Expand neck w mandrel

The main issue I'm having is with brass sizing.

First off, if you look at my chamber print, you'll see that the 0.200 line is 0.502. that is supposed to be 0.200 from the base of the case, right? On both brands of cases, that line is just ahead of the start of the extractor groove, or the head, by maybe 1/16". On my cases that I've fired multiple times, say 4 or more, I measure a diameter of 0.503 at 0.275 from the base, while the head measures 0.499-0.500. That means there is basically a small "hump" just forward of the 0.200 line. This doesn't make sense to me per the chamber print.

Secondly, my sizing die reamer print is 0.498 at the 0.200 line. This should be just right for getting enough sizing at the base to prevent getting"clickers" after multiple reloads. But, after a number reloads my brass will only size down to about 0.502 at that "hump" and I will then get some clickers when shooting.

View attachment 542476

Also, I get way more case growth on each firing than I expected to for an AI case. It grows about 0.003-0.004 every reload. The shoulder diameter is spec'd at 0.482, which a 0.004 delta seems fine for a hunting gun, but the shoulder doesn't spring back much if at all and it actually measures 0.482 after sizing. This to me seems like the culprit for getting a case growth of 0.003 or so every loading.

These are the main issues. Other ones are smaller more easily dealt with things.

I recently bought Eric Cortina's expand mandrel die to use as a base sizer. The description on his site made it sound like it would work for mine, but apparently it has a small 7mm neck hole. It did size the base of my brass well, but it also ruined the case at the neck. So hopefully he'll let me return it. This sparked my anger with this wildcat last night .

View attachment 542477