Mc Fraser

Well-Known Member

My Sinclair/Wilson Ultimate SS Micro trimer says Your answer is wrong.. In both applications it would require your head space to be exact in a sample group of cases. "FLS or fireformed and shoulder bumped back, Collet and expanded." The only time I find an issue, is with brass from "some" auto's or semi auto rifles AR-15/AR-10 where the base has really taken a beating from multiple firings and reloads. They require a little lite file work to the base and every thing is back in check. I'm sorry if I'm coming off strong but I'm sure the guys using the Girard's are prepping their brass and sorting "Head Stamp" before they trim their brass. I could be wrong on that issue because I don't own one. I will say it like this. As long as my brass is prepped the same, and bases are in spec, and I don't screw up. Every case comes out the same. I measure every one of them so, I know their the same. I ASSUME nothing.

In either case, shoulder or base, the trim is only going to be as good as the prep work put in to it. My little trimmer may not be any where near as fast as the stated. But it's dead up accurate and repeatable 99.9% of the time provided I did not make a mistake some where in the brass prepping.

** The case length from base to shoulder will vary from case to case.** That's true in every case. As long as the Base, Case Body, Shoulder Head Space are Set to The Same Specs, case to case. Why should I care about any thing else. I'm Trimming on the BUSINESS end of the case, as long as that case comes out 1.911 on every case. I'm happy.

JM2C and Opinions do vary on this subject. I say, what works best for you is always the best method at hand. The test will take place down range on the target.

Interesting! Just so we are on the same page, I'm not implying anything, we are discussing trimming operations, in theory.

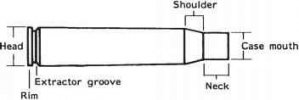

I'm attaching a picture so we can compare apples to apples. My goal is to have a consistent case length, not only from head to case mouth but also consistent neck, shoulder and body length. In my opinion, a FL die in theory will take care of the head to shoulder length, while a trimmer that indexes on the shoulder will take care of the neck length. With these two operations, in theory, and ignoring other external factors, the reloader will have consistent case dimensions - head to shoulder and neck length. With that in mind, a trimmer that indexes on the shoulder will yield consistent neck lengths.

Now, a trimmer that indexes on the head could potentially induce neck length errors if the FL die does not size consistently. Let's assume for a second that the FL die tolerance is +- 1 thou, then it does not matter how "perfect" or "my trimmer does a great job" your trimmer is, that inconsistency will be carried over. We all know that any tool will have a tolerance therefore your neck length at the time of trimming can be very inconsistent. How much it depends on the added tolerance from each operation.

Does it matter in real life? To me yes, for other nope.

I want consistent neck length on all my cases, and as far as I know, the only way to do it is with a trimmer that indexes on the shoulder.

I can't comment on the Wilson trimmer, I cant tell from the pictures if the case holder serves just as a centralized or it is machined to stop the case on the shoulder.

Does that make sense?