-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reamer/reloading question

- Thread starter thaught

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

You need clearance of . 004. Sounds about right to me with. 004 neck tension.

Yes, that with the bullet seatedYou need to know the brass thickness in the neck to know what the loaded round diameter is. You say the brass you have is .337". Is that with bullet seated?

sable tireur

Well-Known Member

- Joined

- Oct 8, 2010

- Messages

- 3,943

.346 - .337 = .009"/2 = .0045" per side.

Plenty of room for expansion.

Plenty of room for expansion.

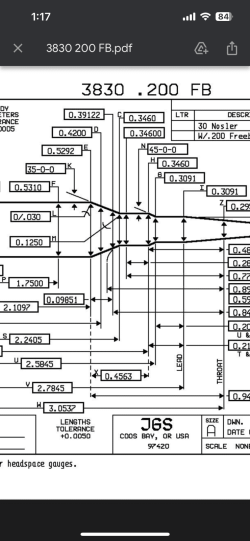

I really don't think you have a problem. I use JGS Reamers and ADG Brass exclusively both are excellent companies. The brass is about perfect if your numbers are accurate. .308 +.014 per side = .336. Every thing has tolerances. You will have to measure a fired case to see if you have a problem and I suspect you do not.

BrBa.

Well-Known Member

.0045" per side seems like a lot to me. I wonder what that much clearance will affect brass life?.346 - .337 = .009"/2 = .0045" per side.

Plenty of room for expansion.

I have a 6.5x55 with a measured 0.006" (0.003" per side) clearance, and I get a ton of soot on the outside of fired case necks.

waveslayer

Well-Known Member

You can always use a custom expander mandrel to get the necks larger or smaller

BrBa.

Well-Known Member

Not sure what you mean.

The inside neck diameter of my chamber is @ .3000". Fired cases measuring .2995" will chamber easily so I assume it's at least .3000". Loaded neck diameter of my rounds are .2940" (.264 with neck turned brass at .015" walls), which is where I got the .003" clearance per side.

Just not used to seeing soot like this on the outside of fired cases.

The inside neck diameter of my chamber is @ .3000". Fired cases measuring .2995" will chamber easily so I assume it's at least .3000". Loaded neck diameter of my rounds are .2940" (.264 with neck turned brass at .015" walls), which is where I got the .003" clearance per side.

Just not used to seeing soot like this on the outside of fired cases.

Attachments

waveslayer

Well-Known Member

my .338 Norma AI does that. All good, it just takes extra cleaning to get the extra ring out, Carbon ring that is. It's a tack driver and shoots so wellNot sure what you mean.

The inside neck diameter of my chamber is @ .3000". Fired cases measuring .2995" will chamber easily so I assume it's at least .3000". Loaded neck diameter of my rounds are .2940" (.264 with neck turned brass at .015" walls), which is where I got the .003" clearance per side.

Just not used to seeing soot like this on the outside of fired cases.

Not sure what you mean.

The inside neck diameter of my chamber is @ .3000". Fired cases measuring .2995" will chamber easily so I assume it's at least .3000". Loaded neck diameter of my rounds are .2940" (.264 with neck turned brass at .015" walls), which is where I got the .003" clearance per side.

Just not used to seeing soot like this on the outside of fired cases.l

Sooty necks are often a sign of low pressure.

How much clearance depends on what you want. Benchrest shooters turning necks after goin around .0005" per side or .001" total clearance. Thats a bit tight for unturned necks as only slight variation from the factory could cause an unsafe condition. Many "no turn" match chambers are roughly .002" total clearance, but are designed for specific brass and you can't change brands without carefully checking. Plenty of factory chambers have more clearance than what you're showing.

BrBa.

Well-Known Member

Those cases were running 140s at 2850, so not low pressure, probably @ 63 ksi. I had a couple firings on them without annealing, so I'll see if it makes any difference next time.Sooty necks are often a sign of low pressure.

Sooty necks often go away with a tad more powder and long before pressure signs arrive, but perhaps I usually have less neck clearance than you. I can't say for sure I guess.Those cases were running 140s at 2850, so not low pressure, probably @ 63 ksi. I had a couple firings on them without annealing, so I'll see if it makes any difference next time.