Hey all,

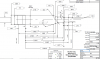

So I had a 7-300 win built for me by Rbros rifles late last year and love everything about it! I love it so much I wanted to build one for my Dad. I called PTG and talked with Dave and ordered a 7-300 win reamer with no shoulder changes and a long throat for a 180 vld. I got an email with the print, and I'm no pro at reading prints, but everything looked great. First pic is that print

http://www.longrangehunting.com/forums/attachment.php?attachmentid=45704&stc=1&d=1425954673

Six days later I got another email from PTG with what I thought was the same print, but it said 7mm pratical. I didn't look it over very well, and now I notice that it has a 30 degree shoulder. The reamer showed up, I gave it to my gunsmith and he cut the chamber. A 300 win go gauge closes in the chamber just fine, but I couldn't get the brass I had prepared to chamber. On closer inspection, I realized that the reamer does have a 30 degree shoulder angle and a longer neck. Looking at the print, its very similar to the balistic studies 7mm Practical.

SO, my question is this. I feel like the chamber needs to be cut deeper to acomodate a 30 degree shoulder, but if the go gauge fits as it is, it seems obvious that cutting the chamber deeper would create some serious headspace issues. My thought would be to take the brass I prepared for my other 7-300 that chambers just fine, and cut the problem chamber deep enough to chamber my prepared brass. Then would the brass not fire-form to a 30 degree shoulder and I could continue life as normal with my redding type s neck die?? Any comments would be greatly appreciated.

Thanks

So I had a 7-300 win built for me by Rbros rifles late last year and love everything about it! I love it so much I wanted to build one for my Dad. I called PTG and talked with Dave and ordered a 7-300 win reamer with no shoulder changes and a long throat for a 180 vld. I got an email with the print, and I'm no pro at reading prints, but everything looked great. First pic is that print

http://www.longrangehunting.com/forums/attachment.php?attachmentid=45704&stc=1&d=1425954673

Six days later I got another email from PTG with what I thought was the same print, but it said 7mm pratical. I didn't look it over very well, and now I notice that it has a 30 degree shoulder. The reamer showed up, I gave it to my gunsmith and he cut the chamber. A 300 win go gauge closes in the chamber just fine, but I couldn't get the brass I had prepared to chamber. On closer inspection, I realized that the reamer does have a 30 degree shoulder angle and a longer neck. Looking at the print, its very similar to the balistic studies 7mm Practical.

SO, my question is this. I feel like the chamber needs to be cut deeper to acomodate a 30 degree shoulder, but if the go gauge fits as it is, it seems obvious that cutting the chamber deeper would create some serious headspace issues. My thought would be to take the brass I prepared for my other 7-300 that chambers just fine, and cut the problem chamber deep enough to chamber my prepared brass. Then would the brass not fire-form to a 30 degree shoulder and I could continue life as normal with my redding type s neck die?? Any comments would be greatly appreciated.

Thanks