Hugnot

Well-Known Member

Looking at the Miller stability estimator using equal velocities:It's actually a function of bullet length and shape more than weight. In general yes, heavier bullets are longer and thus require a faster twist, but this isn't always the case. An example would be a 220gr round nose vs. a 168gr AMAX. The 220gr round nose will stabilize in a 1:14 twist but the 168 AMAX won't at the same velocity. Both bullets are the same length.

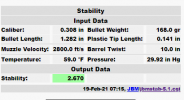

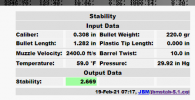

Looking at the Miller stability estimator using load manual velocities for like a .30-06

The 168 AMax has a plastic tip and the Miller estimator treats this by subtracting it from the total length [ ((H9-H10)/H7)^2)) ] or giving the plastic tip no mass (weight) consideration. In this case the plastic tip does affect the Sg, by making the Sg calculator perform the AMax calculation using a shorter length. The shape of the bullet is changed by the plastic tip having no weight (like treated by calculation)..

Verification for above using accepted JBM calculations:

Last edited: