CodyMac746

Well-Known Member

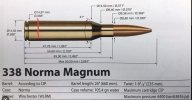

I have a 338 Norma and use rcbs FL die. They are ridiculously hard to get into the die. I've used hornady one shot and unique case lube and they have the same effect. Now I'm noticing my rounds are hard to chamber, took a sharpie to a couple. There's a defined ring at the webbing. After firing, the ring seems to go away and they're easy to eject. It's Lapua brass that is twice fired and annealed. Should I try a different sizing die or is it something else.

Any help would be much appreciated. Thanks in advance

Any help would be much appreciated. Thanks in advance