Hugnot

Well-Known Member

I recently had one of my rifles re-barreled, a 66-year-old FN Mauser. The FN Mauser is a commercial version of the Mauser 98, a battle/war rifle. The 98 types are not smooth & silky to operate but are extremely reliable & tough. Tough enough to handle rounds loaded at normal pressures. The 98 will perform in wet, cold, and filthy battle conditions. The commercial FN version does not have a stripper clip slot, and bolt handle, safety & triggers have been changed.

My rifle was originally a Sears M50. Many of my relatives came from foreign lands (allied side) and upon arrival & citizenship, enjoyed USA gun rights as shown by possession & use of M98's. The 98 was even converted to a 12 ga. shotgun using the 3rd back up safety lug located on the back of the bolt near the bolt handle. The 98 shooting a 7.92X57 (AKA 8X57) 196 gr 8mm bullet at 2550 fps was a strong battle weapon but commonly much lighter bullets were used. The relatively light weight & hard steel stock butt plate made the 98-recoil painful.

My FN Mauser was a natural for the 6mm Rem but 6mm Rem and other brass that can be formed to 6mm Rem like .257 Roberts & 7X57 is difficult to find & very pricy. During the early years of Israeli independence some WWII weapons like ME109's & M98s were used. Many Israeli M98's were re-barreled to 7.62X51 (.308 Win) but not in NW Montana. I re-barreled my FN Mauser to the .243 Win (7.62X51 necked down to 6mm).

Some pics.

The quality of the work is excellent - a complete pleasure to own & use.

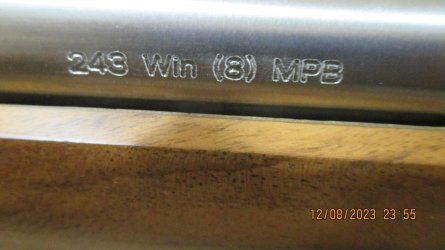

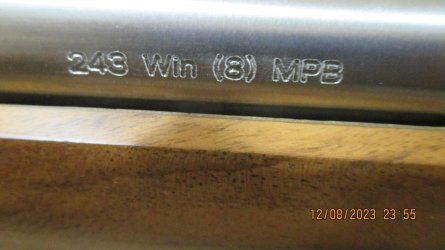

The caliber - .243 Win & twist & other info is shown, stamped on barrel. The precise fit to barrel & receiver ring is shown. The Euro walnut thumb hole stock was designed by JK Cloward. The stock comb is level with bore. Great grain flow. Easy to shoot, reduced muzzle flip up, able to spot hits with light 6mm bullet loads. This is the 4th barrel. Bedding is JB Weld and barrel channel width reduced for thinner barrel also with JB Weld - this also made free floating stock/barrel warp resistant. The non-compressible JB Steel Weld bedding between receiver & bottom metal acts like pillar bedding. The barrel shank was bedded. I did final inletting, shaping, bedding & finishing.

The scope is a Sightron 3-16X42 STAC mounted in Burris Sig Zee rings, front -10 down, back +10 down. This provides enough elevation movement for up to 1,000 plus.

Other different project work is on-going - my policy is courteous, direct, & timely treatment - anything less will cause long-term increasing problems. I have always accepted constructive criticism and used evaluations to assure wise spending.

My rifle was originally a Sears M50. Many of my relatives came from foreign lands (allied side) and upon arrival & citizenship, enjoyed USA gun rights as shown by possession & use of M98's. The 98 was even converted to a 12 ga. shotgun using the 3rd back up safety lug located on the back of the bolt near the bolt handle. The 98 shooting a 7.92X57 (AKA 8X57) 196 gr 8mm bullet at 2550 fps was a strong battle weapon but commonly much lighter bullets were used. The relatively light weight & hard steel stock butt plate made the 98-recoil painful.

My FN Mauser was a natural for the 6mm Rem but 6mm Rem and other brass that can be formed to 6mm Rem like .257 Roberts & 7X57 is difficult to find & very pricy. During the early years of Israeli independence some WWII weapons like ME109's & M98s were used. Many Israeli M98's were re-barreled to 7.62X51 (.308 Win) but not in NW Montana. I re-barreled my FN Mauser to the .243 Win (7.62X51 necked down to 6mm).

Some pics.

The quality of the work is excellent - a complete pleasure to own & use.

The caliber - .243 Win & twist & other info is shown, stamped on barrel. The precise fit to barrel & receiver ring is shown. The Euro walnut thumb hole stock was designed by JK Cloward. The stock comb is level with bore. Great grain flow. Easy to shoot, reduced muzzle flip up, able to spot hits with light 6mm bullet loads. This is the 4th barrel. Bedding is JB Weld and barrel channel width reduced for thinner barrel also with JB Weld - this also made free floating stock/barrel warp resistant. The non-compressible JB Steel Weld bedding between receiver & bottom metal acts like pillar bedding. The barrel shank was bedded. I did final inletting, shaping, bedding & finishing.

The scope is a Sightron 3-16X42 STAC mounted in Burris Sig Zee rings, front -10 down, back +10 down. This provides enough elevation movement for up to 1,000 plus.

Other different project work is on-going - my policy is courteous, direct, & timely treatment - anything less will cause long-term increasing problems. I have always accepted constructive criticism and used evaluations to assure wise spending.

Last edited: