First inspect brass for any defects, 2nd deprime all cases, 3rd put them in my tumbler with Stl.Pins - a pinch of lemi shine and dawn and tumble. Rinse in hot water, remove any St. Stl pins that may still be inside of the cases, spread them on a towel with case mouths all in same direction, Turn on small fan and walk away for several hours. Cases are dried primer pockets are clean and cases spot free.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post brass cleaning?

- Thread starter Lonewolf74

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

John Justice

Member

First step for me is full length sizing and trimming to length. I then wet tumble range brass with Dawn Ultra and Lemi-Shine which makes it look new and cleans out the primer pockets. From the wet tumbler I rinse the brass then dump it directly into my dry tumbler with fine corn cob media which has been treated with Nu-Finish car wax. 15-30 minutes in the corn cob and the brass is completely dry and protected from tarnishing and water spots. After this, I will do any further brass prep that is needed before loading. Existing brass that I have previously wet cleaned and prepped just gets sized and checked with a light dry tumble to remove any sizing lube. Doing this preserves the carbon inside the case neck which aids in consistent bullet seating.

Taj

Well-Known Member

I clean all my brass in a rotating tumbler with Organ TU which is a commercial, organic liguid used by production machine shops for just that purpose. I rinse off the brass then tumble them in dry corncob, which does a great job of getting all the moisture out. Been doing this for many years without an issue. The Organ TU even cleans 99% of the carbon out of the primer pockets.I was wondering what guy's are doing to their brass after cleaning it? Specifically if you wet tumble or ultrasonic clean, how do you keep it from getting water spots and corroding?

FireFlyFishing

Well-Known Member

I de-prime all brass first. Some cartridges can get washed with others. Some, not so much. I will de-prime brass when I come home from the range and throw it in the wash container for storage.

When I have a decent amount of brass to wash, I fill the container with warm water, one drop of dawn, and no more than a table spoon of Lemi Shine.

I wash the brass 2-3 hours. This depends on the amount of brass to be washed.

Once complete, I drain most of the water. Next, I dump all the brass and pins into a rotating sifter/media separator. Once the pins are separated from the brass, I rinse in my kitchen sink with the dish sprayer very well. I'll shake the media separator very well to remove as much water as possible.

The last step is drying. Here, I use old toaster oven cookie sheets and align them like dominos sitting straight up on the head stamp. I then throw them into my electric smoker with no wood chips at 170 degrees for about an hour. I'll check the primer pockets after the hour. If they're still wet I let them dry more, otherwise they come out.

I used to have issues with water spots and I found the key was to use as little dawn and lemmi shine as possible and rinse the brass well.

When I have a decent amount of brass to wash, I fill the container with warm water, one drop of dawn, and no more than a table spoon of Lemi Shine.

I wash the brass 2-3 hours. This depends on the amount of brass to be washed.

Once complete, I drain most of the water. Next, I dump all the brass and pins into a rotating sifter/media separator. Once the pins are separated from the brass, I rinse in my kitchen sink with the dish sprayer very well. I'll shake the media separator very well to remove as much water as possible.

The last step is drying. Here, I use old toaster oven cookie sheets and align them like dominos sitting straight up on the head stamp. I then throw them into my electric smoker with no wood chips at 170 degrees for about an hour. I'll check the primer pockets after the hour. If they're still wet I let them dry more, otherwise they come out.

I used to have issues with water spots and I found the key was to use as little dawn and lemmi shine as possible and rinse the brass well.

Me too!I gave up on water, pins and washing solutions, even my ultrasonic cleaner is only used to clean chainsaw and engine carbs.

I just tumble my brass in corn Cobb.

Cheers.

Afrikaboom

Member

Deprime brass

Lemon shine (small amount) + dawn soap

Stainless steel pins in tumbler

Rinse well, separate stainless steel pins from brass

Place in mesh laundry bag for delicates on shoe rack in tumble dryer, normal cycle

Lemon shine (small amount) + dawn soap

Stainless steel pins in tumbler

Rinse well, separate stainless steel pins from brass

Place in mesh laundry bag for delicates on shoe rack in tumble dryer, normal cycle

I'm always surprised at the lengths people go to dry brass. Maybe I'm lazy, but I just plan ahead so I don't need to load my brass the day I tumble it.

Here's what works well for me.

After wet tumbling, brass and pins go into rotary separator. A few turns and the pins are out of the brass. Then I crank the handle at high speed for a few turns and that blows some water off with centrifugal force.

Then I open the separator and put in 10 or so dry paper towels (I like the heavier duty Viva brand). Rotate drum for 30 seconds. That will absorb 98 percent of the water on the outside of the case, so no water spots.

Dump brass out onto a towel and let dry overnight. I let the paper towels air dry and reuse them many times to save a little money.

Hope that helps.

Here's what works well for me.

After wet tumbling, brass and pins go into rotary separator. A few turns and the pins are out of the brass. Then I crank the handle at high speed for a few turns and that blows some water off with centrifugal force.

Then I open the separator and put in 10 or so dry paper towels (I like the heavier duty Viva brand). Rotate drum for 30 seconds. That will absorb 98 percent of the water on the outside of the case, so no water spots.

Dump brass out onto a towel and let dry overnight. I let the paper towels air dry and reuse them many times to save a little money.

Hope that helps.

X3Me too!

Floridahunter

Active Member

Deprime

Clean/square primer pockets

Spin neck/shoulder in 0000 steel wool to remove hard carbon

Tumble in corn cob media

Anneal

Size

Tumble to remove case lube

Trim if needed

Chamfer and debut case mouth

Mark extracted grove with spring loaded punch to indicate how many time fired.

Clean/square primer pockets

Spin neck/shoulder in 0000 steel wool to remove hard carbon

Tumble in corn cob media

Anneal

Size

Tumble to remove case lube

Trim if needed

Chamfer and debut case mouth

Mark extracted grove with spring loaded punch to indicate how many time fired.

Kyle,Deprime

Clean/square primer pockets

Spin neck/shoulder in 0000 steel wool to remove hard carbon

Tumble in corn cob media

Anneal

Size

Tumble to remove case lube

Trim if needed

Chamfer and debut case mouth

Mark extracted grove with spring loaded punch to indicate how many time fired.

Do you have a pic of exactly where you marks are showing how many times fired?

Pdd

Kyle,

Do you have a pic of exactly where you marks are showing how many times fired?

Pdd

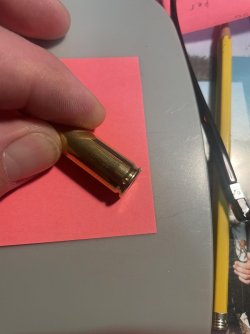

Attachments

The things we used to make out of old washing machine motors. The washing machines may have broken down, but those motors ran forever. Nice tumbler!This home made tumbler can hold 300/400 06 or magnum size cases at a time. BUT, don't mix large & small cases in the same batch or you will spend hours getting them separated.