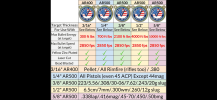

I got it done and one surprised me and I learned something today. I knew velocity mattered and no question it did for sure. 100 yards with it leaned against a solid backer with no flex or give. Shot clockwise starting at 9pm, and finished with the center right shot. I flipped the disc over for the back, so marks are opposite. I then took closer shots trying to show the amount of dimpling. The largest dimple besides the

hole was the 300WSM.

20" plow disc $48, weighs 15#, and is .180 thick.

1 - 223 55FMJ 3100fps

2 - 223 55VMAX 3250fps

3 - 22-250 50BT 3900fps Went through pretty much like butter. This one surprised me and I expected maybe a little cratering.

4 - 300WSM 180 AB 3050fps Slight crack on back with no light visible.

5- 28N 160AB 3350fps Shot this one dead center on metal and dented it less than the 300