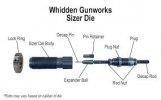

Remove the expander ball if you're going to open the neck with any type of mandrel.

One of the main places runout is introduced is the expander ball.

The problem with most FL dies is they "squeeze" the neck down much too far. And even though there is "spring back", you still end up working against yourself. When you pull that ball back through that much too tight neck, it has the strong possibility of pulling it out of alignment. And often does.

Opening the neck back up with a concentric mandrel will greatly reduce and hopefully eliminate that.

I deprime with universal deprimer. Anneal. Bump shoulder with Redding Body Die. Then add correct neck tension with Lee Collet Neck Die.

"This is the way". Not that it's the only way, but these steps have really refined process. This is giving me the most accurate, consistent ammo I have made to date.

I can really tell the difference in the force required to seat the bullet. It's always the same now and it doesn't take much. This is a function of neck tension. Too much neck tension when seating the bullet and again you induce runout and error creating inconsistent rounds. Inconsistent neck tension can also lead to more ES and SD. When seating now, any little difference can be felt.

The reason I went with my current setup is that even when using a standard full length die with the expander removed, and then using an expander mandrel I found that I still had to much neck tension which then led to too much force to seat the bullets and the inconsistency noted above. Even with a properly sized mandrel the necks have been undersized too much and I ended up with too much neck tension. It's a balancing act too be sure. It was better than using the expander ball alone, or using both the expander ball and mandrel, but still wasn't giving me the desired outcome. Oh, and you don't have to turn necks. I just wasn't interested in that kind of time or effort commitment.

I have no issues with setback and if I need a little more neck tension I will kiss it with the Lee Factory Crimp Die. I have a little experimenting with this and have found no difference in the consistency or accuracy of the final product.

As far as specific FL dies go, the Forster are some of the best I have found if you're going to use the expander ball. This is due to their placement of the expander ball much higher up in the die body so that when the ball is pulled back through the neck the neck is more supported inside the die. It's a slick design. I have one in almost every rifle caliber I load. I also find the Forester dies tend to not undersize the neck quite so much. And if you want you can have Forster custom grind the neck to your specific dimensions. And they are reasonably priced. If you can find them in stock.

Lastly, I'm not saying this is the only way, or even the best way to get the desired results. Just giving you my observations.