birdiemc

Well-Known Member

I know I have to start annealing, yesterday I was trying to work up a load and had a neck split wide open on my second to last round, then went back and looked over the rest with a flashlight and found 2 more with hairline cracks.

1.Do the split necks screw up the velocity data I gathered?

Rifle, 308win, 20" barrel suppressed, remington 700 in magpul hunter stock.

Shooting 168smk, Varget 42.0-46.0 in .4 gr increments.

Brass prep, twice fired federal brass. Not tumbled. Using lee press and dies. FL sizing die bumped shoulder back .002. Measured all with comparator, all exactly equal. Did not trim or measure this firing, previous firing trimmed to 2.007 (nothing magical about that number just didnt want to screw up and overshoot trying to get to 2.005) lee delux case trimmer. Cleaned primer pockets, seated primers with lee handheld, primers vary from .001-.006 below base of case. Seated bullets as long as they will fit into my magazine, avg COAL 2.885, CBTO varied only .001 (as good as I could get with equipment I have). Did not sort bullets or cases by weight. Using lee beam scale. Tediously measured powder trying to get the exact perfect charge. Triple checked my numbers before filling the case, then checked again before moving on to the next charge.

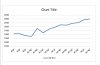

2385, 2377, 2478, 2422, 2469, 2495, 2526, 2521, 2545, 2552, 2591, 2601

Checked over magnestospeed.

2. Based on everything I've said so far and the velocities I recorded, is this worth even looking at, or do I have too many things working against me to make any sense of this?

I will say when looking at this on a spreadsheet I noticed loads 7,8,9,10 only have a 31fps spread, which is what many have one to the next so was thinking about picking the middle there and loading up and down .2 gr in .1 gr increment and see what I get. What would any of you do if you were in my shoes?

I do intend to get a flsh hole deburring tool either sinclair or k&m, as well as primer pocket uniformer.

I bought a cheap hornady digi scale today so I can start sorting brass and bullets, the thought of doing that on that lee beam scale, well it kept me from doing it. I have started keeping track of brass, labeled in zip lock bags by headstamp and number firings. Trying to go in the right direction just cant afford to buy everything all at once.

Edited to add rifle info

Edited again to put correct starting charge weight, accidentally typed 44gr when it was actually 42 gr

1.Do the split necks screw up the velocity data I gathered?

Rifle, 308win, 20" barrel suppressed, remington 700 in magpul hunter stock.

Shooting 168smk, Varget 42.0-46.0 in .4 gr increments.

Brass prep, twice fired federal brass. Not tumbled. Using lee press and dies. FL sizing die bumped shoulder back .002. Measured all with comparator, all exactly equal. Did not trim or measure this firing, previous firing trimmed to 2.007 (nothing magical about that number just didnt want to screw up and overshoot trying to get to 2.005) lee delux case trimmer. Cleaned primer pockets, seated primers with lee handheld, primers vary from .001-.006 below base of case. Seated bullets as long as they will fit into my magazine, avg COAL 2.885, CBTO varied only .001 (as good as I could get with equipment I have). Did not sort bullets or cases by weight. Using lee beam scale. Tediously measured powder trying to get the exact perfect charge. Triple checked my numbers before filling the case, then checked again before moving on to the next charge.

2385, 2377, 2478, 2422, 2469, 2495, 2526, 2521, 2545, 2552, 2591, 2601

Checked over magnestospeed.

2. Based on everything I've said so far and the velocities I recorded, is this worth even looking at, or do I have too many things working against me to make any sense of this?

I will say when looking at this on a spreadsheet I noticed loads 7,8,9,10 only have a 31fps spread, which is what many have one to the next so was thinking about picking the middle there and loading up and down .2 gr in .1 gr increment and see what I get. What would any of you do if you were in my shoes?

I do intend to get a flsh hole deburring tool either sinclair or k&m, as well as primer pocket uniformer.

I bought a cheap hornady digi scale today so I can start sorting brass and bullets, the thought of doing that on that lee beam scale, well it kept me from doing it. I have started keeping track of brass, labeled in zip lock bags by headstamp and number firings. Trying to go in the right direction just cant afford to buy everything all at once.

Edited to add rifle info

Edited again to put correct starting charge weight, accidentally typed 44gr when it was actually 42 gr

Last edited: