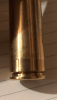

All my cases from last time I shot have these distinct part were everything above the line is shinny/reflective brass while everything below the line is dull. Maybe the dull portion of the case is the part that expanded?

These loads were intro loads and this was the second time the brass has been fired. Primers look great and bolt lifted very easy after firing.

Green arrow is pointing to the dividing point between shinny and dull brass.

Cases were clean and shot in my chamber and then were put right back into the box. Did not touch the ground or any dirt.

These loads were intro loads and this was the second time the brass has been fired. Primers look great and bolt lifted very easy after firing.

Green arrow is pointing to the dividing point between shinny and dull brass.

Cases were clean and shot in my chamber and then were put right back into the box. Did not touch the ground or any dirt.