DUSTY NOGGIN

Well-Known Member

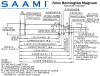

so a headspace chamber dimension for belted magnums is between .220 & .227

i am guessing here , so please correct me

is a no go gauge is going to be .220 ??

is a go gauge .2235 ???

is a field gauge .227 ???

i thought id try and build some , since no gos are back ordered

i am guessing here , so please correct me

is a no go gauge is going to be .220 ??

is a go gauge .2235 ???

is a field gauge .227 ???

i thought id try and build some , since no gos are back ordered

Attachments

Last edited: