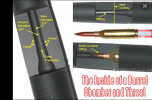

Yes, something does seem to be off with that to me also but was also told that that is just where the rifling started in the chamber. although if the throat was cut concentric to start with it looks like to me anyway, that there should be no reason for there to only be rifling right at that one spot. But I am not a gunsmith and this is my first CA, first semi custom rifle for that matter.Looking at your pictures of your fired cases it does appear that the firing pin detent seems to be off center. That along with rifling marks on only one side would lead me to believe things are not concentric throughout. The rifling marks almost touch the tip of the case neck which indicates a very short free bore in your chamber. I would be of the thought to send it back and have them put a proper concentric with the action barrel. Just my thoughts. Sheldon

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brand new CA Ridgeline 300 PRC Chambering issue?

- Thread starter .280AI Freak-Nasty

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

RockyMtnUT

Well-Known Member

Just for kicks...pull a bullet out of cartridge and cycle the new brass into the rifle. Without the bullet does it cycle smoothly?

Trying to rule out Chamber,Throat,Leade.

Then use a sharpie and color the bullet "Black" then cycle it in and out one time. It will show where its contacting easier also.

Trying to rule out Chamber,Throat,Leade.

Then use a sharpie and color the bullet "Black" then cycle it in and out one time. It will show where its contacting easier also.

Attachments

Last edited:

Well....I had a similar experience last year when I had purchased my CA Ridgeline Titanium in 300 PRC.

1st Barrel:

I too had signs of pressure (actually had one blown primer) and rifling marks on the bullet. Had roughly 120 rounds through and couldn't get it to group. Sent it back and they rebarreled it.

2nd Barrel:

They sent back two test targets ensuring it met the 1" guarantee. I got about 75% through the break-in process and got fed up that I was still getting rifling marks on the bullets and it was extremely tight to close and open the bolt. I took it to a local gun smith just to check it out. He said there was zero free bore and that's why the bullets were getting jammed into the lands.

Sent it back again and the turnaround was much quicker this time. They rebarreled, checked headspace, and bedded the stock. Sent two test targets back ensuring 1" guarantee

3rd Barrel:

TBD....I haven't shot it since receiving. It has six rounds from CA through it and is now up for sale. I bought a Fierce CT Rival in 300 PRC....for $500 more, it just seems more bang for your buck all around........

I wouldn't expect any of this with factory rounds....

I know stuff happens and many people have CA's that are tack drivers....I was not fortunate to have such an experience.

1st Barrel:

I too had signs of pressure (actually had one blown primer) and rifling marks on the bullet. Had roughly 120 rounds through and couldn't get it to group. Sent it back and they rebarreled it.

2nd Barrel:

They sent back two test targets ensuring it met the 1" guarantee. I got about 75% through the break-in process and got fed up that I was still getting rifling marks on the bullets and it was extremely tight to close and open the bolt. I took it to a local gun smith just to check it out. He said there was zero free bore and that's why the bullets were getting jammed into the lands.

Sent it back again and the turnaround was much quicker this time. They rebarreled, checked headspace, and bedded the stock. Sent two test targets back ensuring 1" guarantee

3rd Barrel:

TBD....I haven't shot it since receiving. It has six rounds from CA through it and is now up for sale. I bought a Fierce CT Rival in 300 PRC....for $500 more, it just seems more bang for your buck all around........

I wouldn't expect any of this with factory rounds....

I know stuff happens and many people have CA's that are tack drivers....I was not fortunate to have such an experience.

Ok, thanksJust for kicks...pull a bullet out of cartridge and cycle the new brass into the rifle. Without the bullet does it cycle smoothly?

Trying to rule out Chamber,Throat,Leade.

Then use a sharpie and color the bullet "Black" then cycle it in and out one time. It will show where its contacting easier also.

Last edited:

Jeepers! Sounds like they are hit and miss.. I may be better off taking it to a smith and having them re throat it. What good is a warranty if they do not fix it? Seems like a pretty good platform... For $1900, plus Murphy precision titanium base, Zeiss rings and the new Vx6 HD 3-18x 44 I have a decent amount of $ tied up. guess if a smith can make it right I may be money ahead?Well....I had a similar experience last year when I had purchased my CA Ridgeline Titanium in 300 PRC.

1st Barrel:

I too had signs of pressure (actually had one blown primer) and rifling marks on the bullet. Had roughly 120 rounds through and couldn't get it to group. Sent it back and they rebarreled it.

2nd Barrel:

They sent back two test targets ensuring it met the 1" guarantee. I got about 75% through the break-in process and got fed up that I was still getting rifling marks on the bullets and it was extremely tight to close and open the bolt. I took it to a local gun smith just to check it out. He said there was zero free bore and that's why the bullets were getting jammed into the lands.

Sent it back again and the turnaround was much quicker this time. They rebarreled, checked headspace, and bedded the stock. Sent two test targets back ensuring 1" guarantee

3rd Barrel:

TBD....I haven't shot it since receiving. It has six rounds from CA through it and is now up for sale. I bought a Fierce CT Rival in 300 PRC....for $500 more, it just seems more bang for your buck all around........

I wouldn't expect any of this with factory rounds....

I know stuff happens and many people have CA's that are tack drivers....I was not fortunate to have such an experience.

Shane Lindsey

Well-Known Member

- Joined

- Jul 13, 2010

- Messages

- 3,335

Those do not look like rifling marks to me. They look more like A. Loading from the mag box and dragging up the feed ramp and into the chamber or B. Single feeding doing similar as it seats into the throat. Unfortunately you cannot gently remove them from this rifle. If you could, they would probably be on the bottom side due to gravity.

"Tight chamber" to me sounds like, barely spec'd reamers to allow for max chambering jobs so as it gets closer to worn out, it still has life left in it. I am not a GS and do not know anything about anything so take it FWIW.

I would be curious to see if they actually head spaced this before it went out. I would be willing to say if ANY riflesmith had this come out of the shop, they would demand you send it back as it is their name on it. Christensen obviously isn't concerned with the explosive device you are placing next to you face.

I would get the name of the individual that gave you this advice and ensure you speak to the manager/owner if possible. His employee is fielding phone/emails regarding these explosive containing devices next to your face and stating it is normal. IT IS NOT NORMAL.

Christensen also states they do not warranty if you handload so if you cannot shoot the exact ammo that was designed around the 300 PRC or handload ammo for the 300 PRC, what does Christensen advise?

I too had a Christensen barrel, it was not chambered by them, but it did pressure up faster than I would have preferred.

I recently had another barrel company that chambered a prefit for me, refuse to acknowledge something wasn't right. It was slower than posted velocities, it pressured faster than posted velocities, was very inaccurate. Regardless of how big these companies think they are, they cannot continue to put out garbage and expect to stay around long. The internet crushes business these days.

Sorry rant over.

Glad you are sending it back. Too bad it was a gift, or I would advise having Christensen send you your money back and getting one from a company that stands behind their name.

"Tight chamber" to me sounds like, barely spec'd reamers to allow for max chambering jobs so as it gets closer to worn out, it still has life left in it. I am not a GS and do not know anything about anything so take it FWIW.

I would be curious to see if they actually head spaced this before it went out. I would be willing to say if ANY riflesmith had this come out of the shop, they would demand you send it back as it is their name on it. Christensen obviously isn't concerned with the explosive device you are placing next to you face.

I would get the name of the individual that gave you this advice and ensure you speak to the manager/owner if possible. His employee is fielding phone/emails regarding these explosive containing devices next to your face and stating it is normal. IT IS NOT NORMAL.

Christensen also states they do not warranty if you handload so if you cannot shoot the exact ammo that was designed around the 300 PRC or handload ammo for the 300 PRC, what does Christensen advise?

I too had a Christensen barrel, it was not chambered by them, but it did pressure up faster than I would have preferred.

I recently had another barrel company that chambered a prefit for me, refuse to acknowledge something wasn't right. It was slower than posted velocities, it pressured faster than posted velocities, was very inaccurate. Regardless of how big these companies think they are, they cannot continue to put out garbage and expect to stay around long. The internet crushes business these days.

Sorry rant over.

Glad you are sending it back. Too bad it was a gift, or I would advise having Christensen send you your money back and getting one from a company that stands behind their name.

No problem, I appreciate your advice. The bullets were not loaded from the mag box they were fed into the action single shot. and it made those striations on the bullet from the rifling the live rounds are a little hard to chamber and eject as well.Those do not look like rifling marks to me. They look more like A. Loading from the mag box and dragging up the feed ramp and into the chamber or B. Single feeding doing similar as it seats into the throat. Unfortunately you cannot gently remove them from this rifle. If you could, they would probably be on the bottom side due to gravity.

"Tight chamber" to me sounds like, barely spec'd reamers to allow for max chambering jobs so as it gets closer to worn out, it still has life left in it. I am not a GS and do not know anything about anything so take it FWIW.

I would be curious to see if they actually head spaced this before it went out. I would be willing to say if ANY riflesmith had this come out of the shop, they would demand you send it back as it is their name on it. Christensen obviously isn't concerned with the explosive device you are placing next to you face.

I would get the name of the individual that gave you this advice and ensure you speak to the manager/owner if possible. His employee is fielding phone/emails regarding these explosive containing devices next to your face and stating it is normal. IT IS NOT NORMAL.

Christensen also states they do not warranty if you handload so if you cannot shoot the exact ammo that was designed around the 300 PRC or handload ammo for the 300 PRC, what does Christensen advise?

I too had a Christensen barrel, it was not chambered by them, but it did pressure up faster than I would have preferred.

I recently had another barrel company that chambered a prefit for me, refuse to acknowledge something wasn't right. It was slower than posted velocities, it pressured faster than posted velocities, was very inaccurate. Regardless of how big these companies think they are, they cannot continue to put out garbage and expect to stay around long. The internet crushes business these days.

Sorry rant over.

Glad you are sending it back. Too bad it was a gift, or I would advise having Christensen send you your money back and getting one from a company that stands behind their name.

Yep, that is what the owner's manual says also. If any alterations are done to the gun that is not done by Christensen, it voids the waranty.You will probably void your warranty if you touch that chamber with a reamer . Send it back. It's defective!!!!!

Shane Lindsey

Well-Known Member

- Joined

- Jul 13, 2010

- Messages

- 3,335

That looks a little too close to the case mouth to be the rifling. They should be up a little higher on the ogive. They also look too wide to be made from lands. Again I am not a GS so I don't know, I do know something isn't right.

Iv sold all my CA cause its always the bullet fault. Owned 5 CA and had to send 3 back for that reason and got back and still wasn't right so I moved on from them.

I'd send it back...without a doubt! I read this all the time about Christensen. I had one and sold it 2 weeks after I bought it. Bolt was loose and sloppy, they seem to have poor quality control.

700Sendero

Well-Known Member

- Joined

- Apr 25, 2014

- Messages

- 53

If you do a search, you'll find lots of both ends with Christensen, good and bad. I had a bad experience with a Classic in 308, and their CS was horrible. I wouldn't have one if you gave it to me, but I know others who love them. Hopefully they take care of you!