Send it 284

Well-Known Member

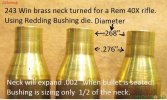

I'm wanting to use a fl bushing die to size a 30 nosler case down .008, this includes .002 neck tension.

Am I going to have runout issues?

I really don't want to use standard dies cuz my

chamber neck diameter is .346 and redding/ rcbs dies will take it clear down to. 334

Am I going to have runout issues?

I really don't want to use standard dies cuz my

chamber neck diameter is .346 and redding/ rcbs dies will take it clear down to. 334