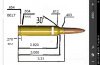

Here is picture of my freebore checking setup, where we used a throater to

make different length freebores in small increments to check bullet fit and

find out how far we could get bore rider bullets out of the powder space,

The bullet in the barrel is a 400gr MTAC with stupid seal band off, The

case behind is with same bullet in it at max length possible and still keep

bullet tight in the case, Its overall length is 5.05", can get 185gr dense ball

powder under it, settled and.compressed.

I'm telling all for absolute top speed, get bore riders,

load them out in longer freebore, so you can get speed without pressure

problems, as Manson, etc will give you any freebore on reamer you want.

If CEBs take off the band so you can use the freebore.

Other 600 cases behind need two more neck swage passes and deburring

and they are all necked, little polishing, photogenic perfect. Ed