If bearing surface changes center of gravity it can be offset by length of boat-tail to nose length. I use sea level for twist minimum references. Bat as earlier posted.....length is more of a factor than weight alone. Sierra for another reference on 30cal 230gr (#2251) requires an 8T 240gr (#9245) 9T and 220gr (#2240) 10T. Close in weight, but bullet parameters are different.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Twist vs Bullet Weight Question

- Thread starter Small Lady

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Mikecr

Well-Known Member

Need to prevent tumbling, or need for full stability? And if the bullet flies through a mosquito fart? What twist then, 6.75?When the 224V load data explains that you need a 90gr (#9290) 6.5T if less than 2,650fps and 7T if equal to 2,650fps. Bullet parameters didn't change, but twist requirements did.

Small Lady

Well-Known Member

I doubt stability differences are significantly tied weight differences. That just fails too many tests.

Stability is tied to center of mass -vs- center of pressure. This, creating an overturning arm, the length of which depends on their spread.

Longer bullets (regardless of weight) tend to exhibit more overturning moment -because their center of mass falls further behind center of drag.

Higher drag causes the center of pressure to be higher w/respect to center of mass.

Both must be overcome with gyroscopic inertia per overturning displacement (not per time)(forget RPMs).

And consider the reality that gyroscopic inertia would not be needed for bullets in the vacuum of space.

Honestly, that just made me have more questions lol.

Since spin, twist, rpm, whatever you want to call it is needed to keep a bullet flying accurately, then why not just spin all of them as fast as possible?

They will all tumble at some point, just some do it earlierNeed to prevent tumbling, or need for full stability? And if the bullet flies through a mosquito fart? What twist then, 6.75?

Calvin45

Well-Known Member

Some folks do indeed take this approach. There will be all manner of contentious debate about the nature and existence of "overstability". But one thing is certain: more twist than needed always beats not enough!Honestly, that just made me have more questions lol.

Since spin, twist, rpm, whatever you want to call it is needed to keep a bullet flying accurately, then why not just spin all of them as fast as possible?

I will say, in my observations and experience, that excessive rpms/faster than necessary twist doesn't have nearly the detrimental effect on accuracy with cartridges .25 cal and smaller that it does with larger bores. My multiple .300 win mags 10 twists have never done well with light bullets at all.

Small Lady

Well-Known Member

For the OP @Small Lady Here's some pictures to illustrate what we've been saying.

Here is a 225 eld m and a 200 SMK (.30 cal) beside each other, bases flush against a butter knife. The 225 is heavier obviously BUT as you can see, it is longer too.

View attachment 507343

HOWEVER….hornady lists the minimum stability twist as 1:10, Sierra as 1:9.

Here, I have them beside each other BUT with the transition points from shank to ogive being parallel (as crudely determined by etching a little ring into them with a resized .300 win mag case mouth. As you can see, the ogive on the 200 SMK is actually longer than the 225 eldm.

View attachment 507344

Finally, side by side with boat tail/shank junctions parallel. Again, the smk is just a more "severe" and less forgiving bullet: it's boat tail is notably longer than the eld too!

View attachment 507345

These things are why it actually does take more twist to stabilize this smk: longer ogive, longer boat tail, waaaaaaay shorter bearing surface, and definitely more aggressively rear heavy all means it's less stable at a given twist .

Thanks for this, that truly helped.

Especially when talking about rear biased weight distribution.

In much the same way a longer boat is more stable than a short boat, but regardless of its length a boat must have weight distributed evenly along its length. Hang an over sized outboard on the transom, and then put 10 friends all at the back, it will handle terribly.

CaneBrake

Well-Known Member

There are very little, if any, downsides to having too fast of a twist rate. The only reported issue I have heard of but never seen is that it can cause the bullet jacket to deform or completely delaminate from the core. That may be from older days when bullet technology wasn't as good.Honestly, that just made me have more questions lol.

Since spin, twist, rpm, whatever you want to call it is needed to keep a bullet flying accurately, then why not just spin all of them as fast as possible?

memtb

Well-Known Member

There are very little, if any, downsides to having too fast of a twist rate. The only reported issue I have heard of but never seen is that it can cause the bullet jacket to deform or completely delaminate from the core. That may be from older days when bullet technology wasn't as good.

This possibility is completely out of the conversation…..if you use mono bullets.There is no jacket to separate from the core!

However, a heavy mono is generally quite long as compared to a cup and core of similar weight, which takes us back to needing a faster twist to stabilize the mono! memtb

Calvin45

Well-Known Member

Heres another old picture of mine just to show how much bullet length and bullet weight can be disproportionate depending on design.Thanks for this, that truly helped.

Especially when talking about rear biased weight distribution.

In much the same way a longer boat is more stable than a short boat, but regardless of its length a boat must have weight distributed evenly along its length. Hang an over sized outboard on the transom, and then put 10 friends all at the back, it will handle terribly.

120 Barnes tactx, 220 CIL Klingkor round nose, 250 grain hawk round nose, 180 trophy bonded tip, 208 eld m, 210 accubond long range.

Note that the 120 tactx is the same length as the 220 round nose! And the 250 round nose is actually SHORTER than the 180 trophy bonded. Blunt round nose bullets aren't nearly as rear heavy either…makes them suck for long range target shooting and absolutely SMASH as far as terminal performance at close range - straight line penetration! There is a reason you will never see VLD profiles on dangerous game "insurance" bullets

Hugnot

Well-Known Member

Those 225 ELDM & 200 Si MK's are real long pointy bullets needing fast twist rates so they will not fly sideways.

I look for bullets that shoot real good thru my barrels. I know what the twist rate is & can measure the bullet length. Bullets are pricy & I shoot lots of bullets. So before pulling out the VISA plastic I gotta know how good they will shoot.

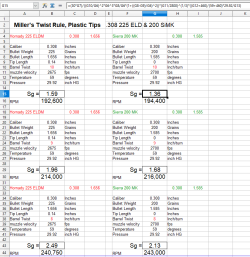

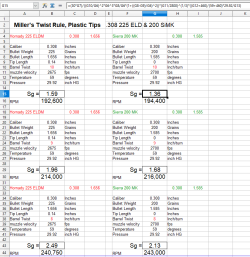

I decided to make an Excel spread so I could check out stuff. I went to Wikipedia so I could look stuff up.

en.wikipedia.org

en.wikipedia.org

I came up with some spread sheets - an example using the .30 225 ELDM & 200 SI MK (new version, old ones were not as pointy but I shot some of them at 1,000 silhouette chickens and they sure swatted the chickens down, .300WM, 10 twist, shorter bullet at 1.393 inches)

If I had a big .30, 10 twist I would not buy the new 200 SI MK's. The 225 ELDM is a real long pointy bullet but some of the length is light plastic & Mr. Miller subtracts the plastic tippy from the overall length(G8-G9 is where operation happens but shown for SiMK, having no plastic tip), treating the plastic as having no effect for bullet center of mass. This operation is shown in the column/row math. The Sg result is an estimate used by JBM & Berger & others- checks out real good, is conservative.

These bullets spin real fast because the gyroscopic forces are needed to keep the bullet flying in a good point first path (no tumbling) plowing thru air (treated like a liquid) makes the center of pressure (CP) in front of center of mass (CM). Should bullets have tails?

en.wikipedia.org

en.wikipedia.org

"In other words, if the axis of rotation of a body is itself rotating about a second axis, that body is said to be precessing about the second axis"

Skin friction/turbulence is another factor.

en.wikipedia.org

en.wikipedia.org

I have a real nice .300WM, 10 twist, Hart barrel rifle built by the smith who won the 1976 Wimbledon match with a 299-21X- 190 Hornady HpBt match bullet (discontinued) My rifle shoots real good with bullets like the old 200 SiMK. I plan to use it against rodents this spring with 178 ELDM's at slightly more than 3,000 fps (one hole groups).

I look for bullets that shoot real good thru my barrels. I know what the twist rate is & can measure the bullet length. Bullets are pricy & I shoot lots of bullets. So before pulling out the VISA plastic I gotta know how good they will shoot.

I decided to make an Excel spread so I could check out stuff. I went to Wikipedia so I could look stuff up.

Miller twist rule - Wikipedia

I came up with some spread sheets - an example using the .30 225 ELDM & 200 SI MK (new version, old ones were not as pointy but I shot some of them at 1,000 silhouette chickens and they sure swatted the chickens down, .300WM, 10 twist, shorter bullet at 1.393 inches)

If I had a big .30, 10 twist I would not buy the new 200 SI MK's. The 225 ELDM is a real long pointy bullet but some of the length is light plastic & Mr. Miller subtracts the plastic tippy from the overall length(G8-G9 is where operation happens but shown for SiMK, having no plastic tip), treating the plastic as having no effect for bullet center of mass. This operation is shown in the column/row math. The Sg result is an estimate used by JBM & Berger & others- checks out real good, is conservative.

These bullets spin real fast because the gyroscopic forces are needed to keep the bullet flying in a good point first path (no tumbling) plowing thru air (treated like a liquid) makes the center of pressure (CP) in front of center of mass (CM). Should bullets have tails?

External ballistics - Wikipedia

- Projectiles like small arms bullets and artillery shells must deal with their CP being in front of their CM, which destabilizes these projectiles during flight. To stabilize such projectiles the projectile is spun around its longitudinal (leading to trailing) axis. The spinning mass creates gyroscopic forces that keep the bullet's length axis resistant to the destabilizing overturning torque of the CP being in front of the CM.

"In other words, if the axis of rotation of a body is itself rotating about a second axis, that body is said to be precessing about the second axis"

Skin friction/turbulence is another factor.

Reynolds number - Wikipedia

I have a real nice .300WM, 10 twist, Hart barrel rifle built by the smith who won the 1976 Wimbledon match with a 299-21X- 190 Hornady HpBt match bullet (discontinued) My rifle shoots real good with bullets like the old 200 SiMK. I plan to use it against rodents this spring with 178 ELDM's at slightly more than 3,000 fps (one hole groups).

Last edited:

Calvin45

Well-Known Member

Interesting read.Those 225 ELDM & 200 Si MK's are real long pointy bullets needing fast twist rates so they will not fly sideways.

I look for bullets that shoot real good thru my barrels. I know what the twist rate is & can measure the bullet length. Bullets are pricy & I shoot lots of bullets. So before pulling out the VISA plastic I gotta know how good they will shoot.

I decided to make an Excel spread so I could check out stuff. I went to Wikipedia so I could look stuff up.

Miller twist rule - Wikipedia

en.wikipedia.org

I came up with some spread sheets - an example using the .30 225 ELDM & 200 SI MK (new version, old ones were not as pointy but I shot some of them at 1,000 silhouette chickens and they sure swatted the chickens down, .300WM, 10 twist, shorter bullet at 1.393 inches)

View attachment 507392

If I had a big .30, 10 twist I would not buy the new 200 SI MK's. The 225 ELDM is a real long pointy bullet but some of the length is light plastic & Mr. Miller subtracts the plastic tippy from the overall length(G8-G9 is where operation happens but shown for SiMK, having no plastic tip), treating the plastic as having no effect for bullet center of mass. This operation is shown in the column/row math. The Sg result is an estimate used by JBM & Berger & others- checks out real good, is conservative.

These bullets spin real fast because the gyroscopic forces are needed to keep the bullet flying in a good point first path (no tumbling) plowing thru air (treated like a liquid) makes the center of pressure (CP) in front of center of mass (CM). Should bullets have tails?

External ballistics - Wikipedia

en.wikipedia.org

Other stuff happens, like precession causing:

- Projectiles like small arms bullets and artillery shells must deal with their CP being in front of their CM, which destabilizes these projectiles during flight. To stabilize such projectiles the projectile is spun around its longitudinal (leading to trailing) axis. The spinning mass creates gyroscopic forces that keep the bullet's length axis resistant to the destabilizing overturning torque of the CP being in front of the CM.

"In other words, if the axis of rotation of a body is itself rotating about a second axis, that body is said to be precessing about the second axis"

Skin friction/turbulence is another factor.

Reynolds number - Wikipedia

en.wikipedia.org

I have a real nice .300WM, 10 twist, Hart barrel rifle built by the smith who won the 1976 Wimbledon match with a 299-21X- 190 Hornady HpBt match bullet (discontinued) My rifle shoots real good with bullets like the old 200 SiMK. I plan to use it against rodents this spring with 178 ELDM's at slightly more than 3,000 fps (one hole groups).

I've heard of some not counting the plastic tip in the equation but it still has to affect something! Right? Or not? Now I'm scratching my head haha.

@Mikecr youve probably thought this to death already (no offence! I appreciate your troubleshooting analyst brain even if it's aggravating when I just wanna believe!

is the overall projectile length INCLUDING the plastic tip important?

And if yes or no, either way….what would you guys make of the extreme massive tip on the 120 Barnes blackout bullet in my picture above?

On the Miller rule the is a place to add plastic tip.Interesting read.

I've heard of some not counting the plastic tip in the equation but it still has to affect something! Right? Or not? Now I'm scratching my head haha.

@Mikecr youve probably thought this to death already (no offence! I appreciate your troubleshooting analyst brain even if it's aggravating when I just wanna believe!)

is the overall projectile length INCLUDING the plastic tip important?

And if yes or no, either way….what would you guys make of the extreme massive tip on the 120 Barnes blackout bullet in my picture above?

Hugnot

Well-Known Member

Miller thinks the weight is not enough to affect the CM, negligible mass compared to rest of bullet but length of bullet determine CP Two L values used one for CM the other for CP.Interesting read.

I've heard of some not counting the plastic tip in the equation but it still has to affect something! Right? Or not? Now I'm scratching my head haha.

@Mikecr youve probably thought this to death already (no offence! I appreciate your troubleshooting analyst brain even if it's aggravating when I just wanna believe!)

is the overall projectile length INCLUDING the plastic tip important?

And if yes or no, either way….what would you guys make of the extreme massive tip on the 120 Barnes blackout bullet in my picture above?

The following reference is provided.

"This adjustment was most reasonable,because the length in the (1 + L2) term is related tothe rotational moments of inertia. That term will bemore accurately estimated by the length of the metalpart of the bullet because the density of copper andlead are close to 10 times the density of the plastictip. Consequently, the length added by the plastic tipdoes little to change the moments of inertia. Incontrast, the other L in the formula originates in thecenter of pressure, an aerodynamic propertydetermined by the shape of the bullet without regardto material density, with a smaller effect from thecenter of gravity. Thus it makes most sense for thisto remain as the total length of the bullet."

Two bullet lengths are used one for CP, the other for CM, tip length subtracted.

Should the big pointy tip on the Barnes 120 Blackout be plastic the Miller process would subtract the tip then calculate Sg. The tip is big enough to have a big effect on CP. Got a feeling that 12 twist or slower would work fine. What are JBM 's Sg values for that bullet with a 12 & 14 twist. The huge tippy thing looks like 1/4 inch long.

Miller calculation -saw the tippy thing off, and Sg will change much, and CP will also be affected by big tip. Got to try running it.

Hornady ELDX & ELDN - no more melting metplats.

On the Miller rule the is a place to add plastic tip.

The above attached reference. Easiest to measure tip to base then subtract length of tip - commonly .12- .14 for Hornady bullets.

Also,

JBM - Calculations - Stability

Compare a JBM Sg calculation using the data as shown on my Excel spread sheet. Allow some variations, like 01 or so for tip length.

Last edited:

Mikecr

Well-Known Member

If you just trim back a bullet nose and replace copper with plastic, bullet stability would take a hit.Interesting read.

I've heard of some not counting the plastic tip in the equation but it still has to affect something! Right? Or not? Now I'm scratching my head haha.

@Mikecr youve probably thought this to death already (no offence! I appreciate your troubleshooting analyst brain even if it's aggravating when I just wanna believe!)

is the overall projectile length INCLUDING the plastic tip important?

But to keep a plastic tipped bullet at the same weight & overall length, bullet makers would add to lead core -in the nose.

This moves CM forward, and the lead added is at a larger cross section near bearing diameter( more inertia).

With that, you can essentially subtract the plastic tip length from calculations, and **** if it doesn't work out right.

A tricky part when using actual stability math (instead of a rule of thumb), could be meplat diameter(MD).

What is the relative MD of a plastic tip, which squishes/melts a bit at high velocities?

MD is huge to drag, so it's huge to BC and stability.

Well you might notice that plastic tipped bullets have no better BC than non-tipped bullets.

That tells me that plastic MD is unchanged overall, -from normal. So I use non-tipped bullet version MD in calcs for both BC and stability.

I am aggravating to most forum people, I'm sure.

Sux, but somebody has to be me I guess..